Used machines for sale

Aluminum can tamper Aluminum can tamper

Main brands:

Angelus, Continental, Dixie Canner, Goetz, Holstein Kappert, KHS, Krones Taxomatic, krones Ultramatic, Levapack, Metalgraf, Mitri Sleap, Paramix Mojonnier, Zegla

|

| Aluminum can tamper |

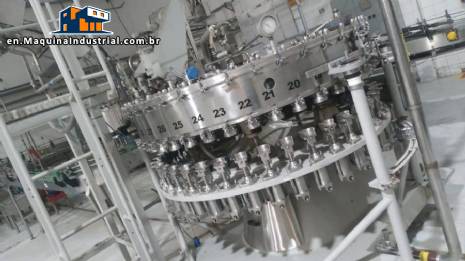

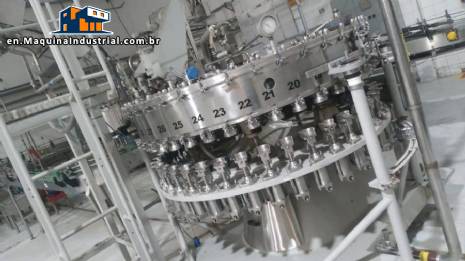

A rotary or linear automatic can crimper is a machine used in the packaging industry to fix or crimp the metal lid on metal cans. This process is crucial to guarantee the hermetic sealing of cans, preserving the quality and integrity of the products stored inside. Here is a more detailed explanation of its function and operation:

1. Heremetic Sealing:

The can seamer's main function is to create an airtight seal between the lid and the can body. This sealing is vital to protect the contents of the can against external factors, such as air, humidity and contaminants, which could compromise the quality and durability of the stored products.

2. Operation:

The general rotary can crimping process involves a few key steps:

Supply of Cans and Lids:

Empty cans and metal lids are fed into the machine automatically. This feeding can be done in-line or in separate stations, depending on the machine design.

Positioning of Cans and Lids:

Cans and lids are precisely positioned to ensure proper alignment during the crimping process.

Reseating:

The machine rotates the cans and lids while applying pressure to crimp the lid into the can body. This process is carried out precisely to ensure an airtight seal.

Inspection and Quality Control:

After crimping, cans can pass through automated inspection systems to ensure proper sealing. This may include visual verification, sensor inspection, or other quality control technologies.

Exit of Sealed Cans:

Successfully sealed cans are then directed to the next step in the packaging process, such as labeling, packaging or other final processes.

3. Variations in Technology:

Rotary can seamers can vary in terms of capacity, speed and technology. Some machines are designed to operate at high speeds to suit large-scale production lines, while others may be better suited for smaller-scale production.

The use of rotary can seamers is common in industries that involve filling food, beverages, chemicals and other products into metal containers. These machines play a crucial role in ensuring the quality and safety of packaged products. |

|

|

|

|

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: Levapack

Automatic seamer for aluminum, PET plastic and tin cans.

Manufacturer | model: LPE | Levapack.

Model: LPE - FHV50V.

With one head.

Stainless steel equipment.

Approximate capacity: 35 to 50 units per minute.

Voltage: 220 V.

Year: ... |

|

|

|

Brand: Levapack

Automatic can seamer for aluminum, plastic and tin cans.

Manufacturer | model: LPE | Levapack.

Model: LPE - FLV 30.

Approximate capacity: up to 30 cans per minute.

Voltage: 220 V.

Year: 2018.

| |

|

|

Brand: Metalgraf

Components: Siemens

4-head seamer for metal cans.

Manufacturer/brand: Metalgraf.

Year: 1994.

With manual.

Approximate capacity: 90 cans per minute.

With panel.

Components: Siemens frequency inverter.

WEG motor.... |

|

|

|

Brand: Brapenta, Masipack, Metalgraf, Neife, SLP Indústria de Máquinas

Components: Siemens, WEG

Can filling system.

Line for filling powdered products in cans, jars and bottles.

The line worked with 400 g cans and a taller 510 g can.

Depending on the density of the product, it can fill up to 600 grams.

- Dosing filling machine for j... |

|

|

|

Brand: BBULL TECHNOLOGY, Zegla

Complete filling line for cans of juices and still drinks.

For Hot Fill cans with nitrogen application.

Manufacturer | brand: Zegla.

Year: 2010 / 2011.

Approximate filling capacity: up to 6000 cans / hour.

Line composed of:

- Depall... |

|

|

|

Brand: Maqmundi

Packaging line for nuts in jars.

Composed of:

- Stainless steel storage table for jars.

Model: LPE - RAT120.

Year: 2018.

- Multi-head dosing scale.

- Input conveyor for feeding the jars.

Model: LPE - PFM01.

Voltage: 220 V.

... |

|

|

|

Seamer for cans.

Approximate measurements:

Height 1600 mm x Width 900 mm x Length 900 mm.... |

|

|

|

Brand: Dixie Canner, Vinox

Brewery factory with tri-block kitchen.

Complete line for beer and draft beer production.

Approximate capacity: up to 15,000 liters.

Year of manufacture: 2018.

For all types of beers and draft beer.

An earth filter was added to optimiz... |

|

|

|

Brand: Toledo

Can filling line for powder products.

It was used to fill cans of powdered milk.

Approximate capacity: from 80 to 100 cans / minute.

For cans with a diameter of 198 mm.

For more information, get in touch.

Line composed of:

- Depalat... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|