Used machines for sale

Beverage Companies Beverage Companies

Main brands:

KHS, Milainox, Mojonnier, Zegla, Ziemann Liess

|

| Beverage Companies |

The beverage industry is diverse and uses a wide range of equipment at different stages of the production process. Here are some of the types of equipment commonly found in the beverage industry:

Processing Equipment:

Fermentation Tanks: For fermentation of alcoholic beverages, such as beer and wine.

Filters and Sieves: For separation of solids and impurities.

Mixers and Homogenizers: To mix ingredients and ensure consistency.

Pasteurizers and Sterilizers: For heat treatment of beverages to ensure safety and stability.

Carbonation Equipment:

Carbonators: To add carbon dioxide to carbonated drinks.

Cooling Equipment:

Heat Exchange: For rapid cooling of beverages after the pasteurization process.

Refrigeration Systems: To keep drinks at ideal temperatures.

Filling and Packaging Machines:

Fillers: For filling bottles, cans or other containers with the drink.

Sealers and Cappers: For sealing and capping packages.

Labeling Machines: To apply labels to packaging.

Automatic Packaging Machines: To pack drinks in larger packages.

Quality Inspection Equipment:

Visual Inspection Machines: To detect imperfections in drinks and packaging.

Metal and X-ray Detectors: To ensure the absence of contaminants.

Filtration Equipment:

Cartridge Filters and Membrane Filters: To remove particles and impurities.

Water Treatment Systems:

Reverse Osmosis and Demineralizers: For purifying the water used in the process.

Concentration and Dehydration Machines:

Evaporators: To concentrate juices or syrups.

Spray Dryers: For production of soluble powders.

Dosing and Measuring Systems:

Ingredient Dosers: To add ingredients in the correct quantity.

Flow Meters: To measure and control the flow of liquids.

Automation and Control Systems:

Automatic Controllers: To monitor and control different production processes.

Cleaning and Sanitizing Equipment:

CIP (Cleaning in Place) systems: For automated cleaning of pipes and tanks.

This list is comprehensive, but the specific selection of equipment will depend on the type of beverage produced (water, juices, soft drinks, beers, spirits, etc.) and the specific processes adopted by the company. It is essential to ensure compliance with food safety regulations and quality standards in the beverage industry. |

|

|

|

|

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: Ecal, Zegla

Syrup preparation equipment | syrup plant for manufacturing soft drinks, juices, and other processed beverages.

Approximate capacity: 5,000 liters per hour of pasteurized product.

Manufacturer | Brand: Zegla.

Year: 2005.

Comprises:

- C... |

|

|

|

Brand: Dixie Canner, Vinox

Brewery factory with tri-block kitchen.

Complete line for beer and draft beer production.

Approximate capacity: up to 15,000 liters.

Year of manufacture: 2018.

For all types of beers and draft beer.

An earth filter was added to optimiz... |

|

|

|

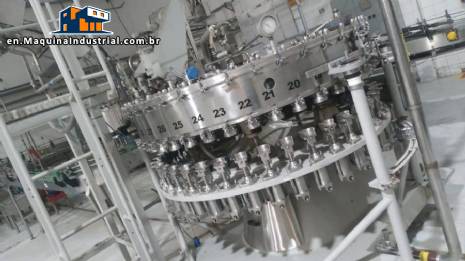

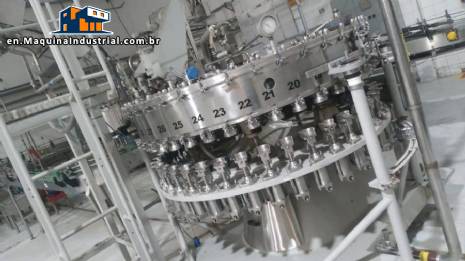

Brand: KHS

Rotary filling machine for carbonated beverages, monobloc, in stainless steel, with 80 valves and filling nozzles.

It has 14 capping valves for Rollon 28 caps.

Manufacturer/brand: KHS

Model: Delta VVF 80/14.

The equipment can be sold as i... |

|

|

|

Brand: KHS, Mojonnier, Sabroe, Schulz, Ziemann Liess

Complete line plant for the production of beer and soft drinks.

Line composed of:

Bottle washer.

Manufacturer: Ziemann-Liess / KHS.

With 32 positions.

Year: 1994.

With tank system.

Linear rinser for bottles.

Nominal production... |

|

|

|

Brand: Milainox

Complete industry company for the manufacture of guarana and teas in cups.

The industry is structured to manufacture two flavors of guarana and three flavors of mate tea.

Approximate productivity: 1000 boxes / day.

Boxes with 24 units.

Fact... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|