Used machines for sale

Depalletizer machine Depalletizer machine

Main brands:

Grown Simplimatic, Zegla

|

| Depalletizer machine |

Depalletizers are industrial machines designed to automate the process of removing products from pallets. They play a crucial role in the supply chain and manufacturing industry, streamlining operations, reducing labor costs and improving efficiency. Let's briefly discuss the usefulness, operation and types of depalletizers:

Utility:

Process Automation: Depalletizers automate the removal of products from pallets, replacing or assisting human labor.

Operational Efficiency: Reduce the time needed to unload goods, speeding up logistics and production processes.

Damage Minimization: Reduces the risk of damage to products during handling.

Operation:

Suction Cup or Claw System: Most depalletizers use a suction cup or claw system to grab and lift products.

Computer Vision or Sensors: Some machines are equipped with computer vision systems or sensors to identify the position of products on the pallet.

Controlled Movement: Depalletizers are designed to move products in a controlled manner, avoiding damage.

Types of Depalletizers:

High Speed Depalletizers: Designed to handle large volumes of goods in high production environments.

Robotic Depalletizers: They use robotic arms to manipulate products, offering flexibility in terms of load types and arrangement on the pallet.

Conveyor Depalletizers: Move products off the pallet using conveyor belts.

Single Layer Depalletizers: Remove products in layers, maintaining the integrity of the stacks.

Magnetic Grab Depalletizers: Use magnets to lift and move metal products, such as cans.

The choice of depalletizer type depends on the specific needs of the industry, the type of products handled, the desired speed and other operational factors. In general, these machines play a fundamental role in optimizing logistics and production processes, contributing to efficiency and cost reduction in industrial operations. |

|

|

|

|

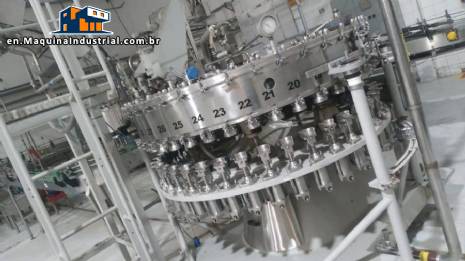

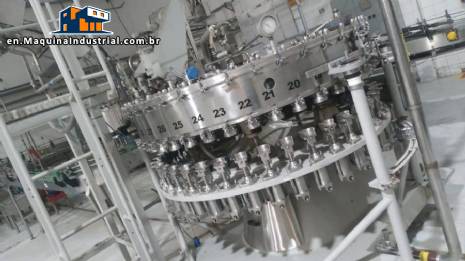

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: BBULL TECHNOLOGY, Zegla

Complete filling line for cans of juices and still drinks.

For Hot Fill cans with nitrogen application.

Manufacturer | brand: Zegla.

Year: 2010 / 2011.

Approximate filling capacity: up to 6000 cans / hour.

Line composed of:

- Depall... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|