Used machines for sale

Rotary filling machines Rotary filling machines

Main brands:

Ablimak, Albermaq, Apitec, APV, Arbras, Bausch, Bramak, Codatec, CompoMaq, Cosmar, Delgo, Dmom, Edward, Engafbras, Erli, Fabrima, Glória, GRC, Gualapack, Holstein Kappert, Hosten, Huhtamaki Brasholanda, Imacal, Imdec, IMSB, Incomaf, Japa Componentes, KHS, Krones, Kugler, LCB, Martinez taboada, Masipack, Mesal, Milainox, Mirainox, Nalbach, Nelpas, Omas, Pack R, Promáquina, Robopac, Rodopac, Ronchi, Rotat, Serac, Sidel, Solbern, Tambflex, Tecman, Velluto Rebelo, Velutto Rebello, Vinox, VMC Máquinas, Wada, WCJ, West equipamentos, Zanasi, Zegla

|

| Rotary filling machines |

A rotary liquid filler is an industrial machine designed to fill containers with liquids in an automated and efficient way. These machines are widely used in various industries, such as food, beverage, chemical and pharmaceutical products, to fill liquids into bottles, jars, containers or packaging. They play a fundamental role in large-scale production, allowing precise, hygienic and rapid filling of liquids. Here is how a rotary liquid filler generally works and what it is for:

Product feeding: The liquid to be filled is fed into the machine from specific storage tanks for the product. The product can be preheated or cooled as needed to maintain the desired viscosity.

Container preparation: Empty containers, such as bottles or jars, are loaded into the machine via a conveyor belt or conveyor system. These containers can be sterilized and positioned appropriately to receive the liquid.

Container positioning: Containers are positioned at filling stations, which are part of the machine rotation.

Filling: While the containers are positioned at the filling stations, the liquid is dosed and inserted into the containers in a controlled and precise manner. This can be done through different filling methods, such as piston dosing, pump dosing, or other dosing systems specific to the type of liquid. Precision in filling is essential to ensure that each container contains the correct amount of liquid.

Sealing: After filling, containers are hermetically sealed with lids, seals or seals. The machine applies the caps or seals and screws, presses, or seals them, depending on the type of cap and the specific machine.

Quality inspection: Filled and sealed containers are often subjected to automated inspections to ensure product quality, such as checking seal integrity, dosage consistency, and possible contamination.

Coding and labeling: Many machines have coding systems to print information such as expiration date, production batch and other relevant data on containers. In addition, they can apply labels with information about the product.

Final packaging: After the filling process, individual containers can be grouped into larger packages, such as boxes, pallets or other types of packaging, as required.

One of the distinguishing features of rotary fillers is the rotation of the filling stations, which allows multiple bottles or containers to be filled at the same time, increasing process efficiency compared to linear machines that operate on a single row of containers. These machines are essential in various industries to ensure the mass production of high-quality packaged liquid products consistently and efficiently.

There are several types of rotary fillers for liquids and pasty products, each designed to meet the specific needs of different products and industries. Below, I will list some common types of rotary fillers for liquids and pasty products:

Rotary filling machines for liquids:

Piston fillers: They use pistons to accurately measure and dose liquids. They are frequently used in the food and beverage industries for products such as juices, milk, oils, syrups, among others.

Peristaltic pump fillers: Use a peristaltic pump to transport liquids and are suitable for products sensitive to contamination, such as pharmaceuticals and biotechnology products.

Gravity fillers: Allow liquids to flow by gravity in containers, suitable for liquids with low viscosity.

Rotary fillers for pasty products:

Piston fillers for pasty products: Similar to piston fillers for liquids, but designed for products with high viscosity, such as sauces, pastes, creams and jellies.

Screw fillers: Specially designed for pasty products, these machines use a screw system to dose and fill products such as toothpaste, cosmetic creams and other high viscosity products.

Lobe pump fillers: Use lobe pumps to dose and fill pasty products, including food products and high-viscosity chemicals.

Plunger or rotary plunger fillers: Use rotary plungers to dose pasty products, such as pharmaceutical gels and high-viscosity cosmetic products.

Each type of rotary filling machine is designed to meet the specific needs of liquid or pasty products, considering their viscosity, density, volume and filling characteristics. The choice of the appropriate machine depends on the characteristics of the product to be filled and the production requirements of the industry in question. Regardless of the type of filling machine, they all aim to provide efficiency, precision and hygiene in the filling process. |

|

|

|

|

Brand: Bausch

Rotary filling machine with sealer and depyrogenation and sterilization tunnel for injectable glass ampoules in 316L stainless steel.

Comprises:

- Automatic rotary filling machine and sealer for glass ampoules for human injection lines.

Manu... |

|

|

|

Brand: Bausch

Automatic rotary filling and sealing machine for glass ampoules for human injection lines.

Manufacturer | Brand: Bausch.

Model: 506.

Year: 2022.

Nominal production capacity: up to 24,000 items per hour, depending on the ampoule size.

E... |

|

|

|

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: Delgo

Stainless steel rotary dosing machine for containers, glasses, and liquids.

Manufacturer | Brand: Delgo.

With automatic sealing for aluminum seals.... |

|

|

|

Brand: Nelpas

Volumetric rotary piston filler for filling small bottles.

Manufacturer: Nelpas.

Piston volume: 100 ml.

Minimum capacity: 30 ml (to be confirmed).

Automatic filling equipment with 4 mechanically driven dosing pistons.

Pneumatic automat... |

|

|

|

Brand: Vinox, Zegla

Gravimetric rotary filling machine in stainless steel with cabin.

Filling machine with capper for 1-liter to 5-liter bottles, drums, and cans, depending on the height and width of the bottle.

Filling by gravimetric nozzles, with 8 nozzles.

W... |

|

|

|

Components: WEG

Rotary filling machine with 12 nozzles and screw capping machine.

For 500 ml PET bottles.

Filling nozzles with return.

With cap feeder for plastic caps.

Equipment already reviewed by Sigma Machines.

With pump and panel.

Components:

... |

|

|

|

Brand: Fabrima, Masipack

Stainless steel filling machine for plastic tubes.

Manufacturer: Fabrima.

Model: EBF 100.

For the manufacturer's catalog click here

... |

|

|

|

Brand: Delgo

Components: Atos, Bonfiglioli, Festo, Moeller, Steck, WEG, Wesen

Dosing filling machine for bottles, flasks and pots for beverages and yogurt.

Brand: Delgo.

Model: MON - L.

Year: 2012.

Dosing system by volumetric cylinder and pneumatic force.

With aluminum seal applicator.

Estimated production: 2... |

|

|

|

Brand: Imacal, Wada

Rotary filling with 12 automatic nozzles.

Brand: Wada, Imacal.

Model: Mr 12.

Double conveyor belt.

In stainless steel.

... |

|

|

|

Brand: Glória

Soda machine.

The equipment in question is used, as is.

Brand of equipment: Glory

production Details:

production: 200 packs per hour.

Number of employees: from 06 to 08 people.

Infrastructure: mt 10 x 20 Mt.

equipment details:

1 Fi... |

|

|

|

Brand: Martinez taboada

Filling machine for vials and flasks with stopper.

Brand: Martinez Taboada.

Model type: Ife 77.

Makes up to 30 ml.

Year: 1979.... |

|

|

|

Semi-automatic filling machine for jars with aluminum lids.

Manufacturer/brand: NTI.

Approximate dimensions:

Height: 1.70 m.

Width: 1 m.

Length: 1 m.

Jar diameter: 100 mm.... |

|

|

|

Brand: BBULL TECHNOLOGY, Zegla

Complete filling line for cans of juices and still drinks.

For Hot Fill cans with nitrogen application.

Manufacturer | brand: Zegla.

Year: 2010 / 2011.

Approximate filling capacity: up to 6000 cans / hour.

Line composed of:

- Depall... |

|

|

|

Brand: Serac

Rotary filling machine for bottles with aluminum seals.

Manufacturer brand: Serac.

Current format: 160 / 180 ml.

Production: 270 thousand bottles per hour.... |

|

|

|

Brand: Delgo, Motomil

Components: Coel, Emeco, Festo, Igus, Onrom, Schmersal, Schneider, SEW, Wenglor

Volumetric filling machine with stainless steel sealer and capper for jars and bottles.

Manufacturer | Brand: Delgo.

Model: DG-2000.

Approximate capacity: 1,200 to 2,000 jars per hour.*

*Depending on the product to be filled.

Approximate... |

|

|

|

Brand: IMSB, Maqmundi

PET bottle filling line with bung capper, labeler, and accumulator table.

Comprises:

- Stainless steel rotary gravimetric filler with 16 nozzles.

With bung capper.

Manufacturer | Brand: IMSB / Rodopac.

Model: EGT8 16 / 4.

Approximat... |

|

|

|

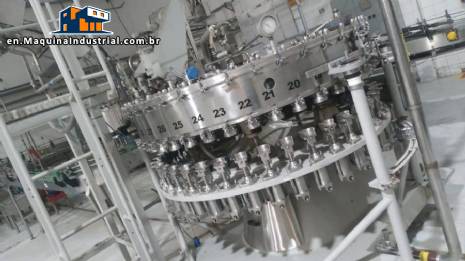

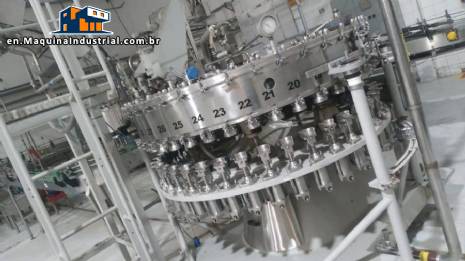

Brand: CompoMaq

Rotary stainless steel filling machine with 30 nozzles.

Manufacturer | Brand: CompoMaq.

For carbonated soft drinks.

For 500 ml, 1500 ml and 2000 ml bottles.

With cap feeder and screw capping machine with 8 heads.

Previously used for so... |

|

|

|

Brand: CompoMaq

Rotaviva filling machine with 42 nozzles and an 8-head screw capper.

Manufacturer | Brand: CompoMaq.

For bottles from 600 to 1000 ml.... |

|

|

|

Brand: Narita, VMC Máquinas

Complete line for bottling mineral water, carbonated or still drinks.

Manufacturer | Brand: VMC Máquinas.

For 500 ml bottles.*

*Can be used for up to 2 liters.

Composed of:

- Inlet air vents that leave the blower* and go to the filler.... |

|

|

|

Brand: Narita, VMC Máquinas

Complete 20-liter water bottling line.

Comprising:

- Rotary bottle filler for 20-liter bottles.

Manufacturer | Brand: VMC Máquinas.

Approximate capacity: 1,600 to 1,800 gallons per hour.

- Washer-rinser for gallons with 10 wash stages.... |

|

|

|

Brand: Delgo

Components: WEG

Automatic stainless steel rotary filling machine with aluminum seal and capping machine for jars and bottles.

Manufacturer | Brand: Delgo.

Model: DG 545.

For filling açaí and ice cream.

The equipment worked with 170 gram açaí and granola ... |

|

|

|

Brand: Ziemann Liess, APV, Cleaver-Brooks, Filtec, Ingersoll Rand, KHS, STEINECKER

Complete Brewery Factory.

Approximate capacity: up to 10,000 bottles/hour for 600 ml bottles.

Equipment set for malt and gritz treatment, consisting of:

- Reception, cleaning and weighing.

Manufacturer | brand: ZIEMANN LIESS (Brazil).

... |

|

|

|

Brand: IMSB

Stainless steel rotary gravimetric filling machine with 16 spouts.

With bung capper.

Manufacturer | Brand: IMSB / Rodopac.

Model: EGT8 16 / 4.

Approximate maximum nominal speed: 6,000 units/hour.*

*For 500 ml and 750 ml bottles.

Speed... |

|

|

|

Brand: Engafbras

Automatic rotary filling machine in stainless steel with 9 monobloc nozzles for liquids.

Liquid filling line with conveyor belts, container rinsing, filling, corking and capping.

Manufacturer/brand: Engafbras.

Approximate capacity: 2,500 lit... |

|

|

|

Rotary filling machine with 48 nozzles.

Year: 1993.

The equipment has been adapted.

It was used for cachaças and alcoholic cocktails.... |

|

|

|

Brand: Japa Componentes

Stainless steel filling machine with 11 nozzles and cork stopper.

Manufacturer/brand: Japa components.

Filling machine model EVR 11-1.

Year: 2014.

For 1500 ml, 3000 ml and 4600 ml bottles.

Cork capper model RLH1.

Year: 2013.

It w... |

|

|

|

Automatic rotary filling machine with 36 nozzles for bottles and glass jars.

For 600 ml glass bottles.... |

|

|

|

Rotary automatic filling machine for soft drinks with 72 nozzles.

For manufacturing carbonated (carbonated) drinks.... |

|

|

|

Brand: KHS

Rotary filling machine for carbonated beverages, monobloc, in stainless steel, with 80 valves and filling nozzles.

It has 14 capping valves for Rollon 28 caps.

Manufacturer/brand: KHS

Model: Delta VVF 80/14.

The equipment can be sold as i... |

|

|

|

Brand: KHS, Mojonnier, Sabroe, Schulz, Ziemann Liess

Complete line plant for the production of beer and soft drinks.

Line composed of:

Bottle washer.

Manufacturer: Ziemann-Liess / KHS.

With 32 positions.

Year: 1994.

With tank system.

Linear rinser for bottles.

Nominal production... |

|

|

|

Brand: OCME, ROMI, Sidel

Bottling line for mineral water.

Line composed by the main equipment:

Pet bottle blower.

Manufacturer: Roma.

Filling and capping system for pet bottles.

Manufacturer: Sidel.

Rotary labeller.

Manufacturer: Sidel.

Model:... |

|

|

|

Brand: Arbras

Filler filling machine 32 filling nozzles.

Manufacturer: Arbras.

Model: M2F-32-PP.

Approximate productivity: up to 12,000 vials/hour.

With 8 capping arms.

Worked with vinegar.... |

|

|

|

Brand: Edward

Automatic rotary filling machine 20 nozzles with gravity filler and closing machine.

Brand: Edward.

Approximate capacity: 500 ml.

Year: 2019.

It has:

Dosage control via level.

01 central tank for feeding with level control.

01 li... |

|

|

|

Filling 20 rotating nozzle for liquids. Ideal for filling, bottling soda syrup, juice Pack and fill bottle of soda, among others.... |

|

|

|

Brand: Pack R

2

Rinsers Machines N° series: 98034

01/1999 Manufacturing

v

400 Volts Frequency 60 Hz

Amps

12 v. 8000V. The

air pressure 6 Bar... |

|

|

|

Brand: Holstein Kappert

* Tampador * head * 12 k12k Holstein * Year 1985 ... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|