Used machines for sale

Colloid mills Colloid mills

Main brands:

Fryma, Frymakoruma, Incal, Meteor, ProXES, Shanghai Zhuheng Industrial, Tetra Pak

|

| Colloid mills |

A colloidal mill is equipment used to reduce the size of solid particles or liquid droplets in suspension or emulsion. It is especially useful in the production of products such as pastes, creams, suspensions and emulsions. Let’s explore what a colloidal mill is for and how it works:

What is it for:

Fine Grinding: The colloidal mill is designed to perform fine grinding and homogenization of solid materials in suspension or liquids in emulsion.

Emulsion Production: It is widely used in the production of emulsions, where oils or fats are dispersed in an aqueous phase, resulting in a stable mixture.

Food Product Processing: Found in food industries for the production of nut butters, mayonnaise, sauces, fruit spreads, among other products.

Pharmaceutical Industry: Used for the preparation of pharmaceutical suspensions, creams, ointments and other pharmaceutical products.

Cosmetics and Personal Care: Used in the production of creams, lotions, gels and other personal care products.

Chemical Industry: Used for the homogenization and fine grinding of chemicals, pigments and additives.

How it works:

Grinding Chamber:

The colloidal mill has a grinding chamber where particle size reduction occurs.

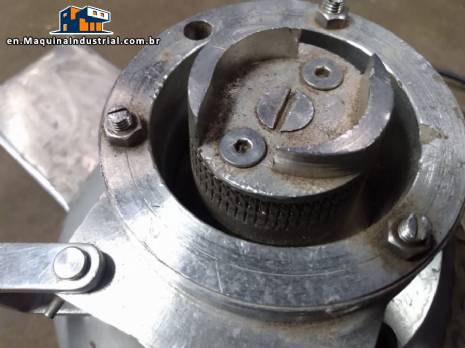

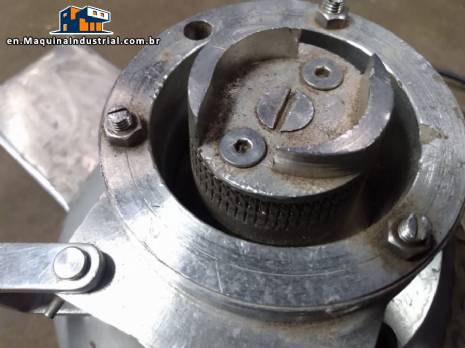

Rotor and Stator:

Inside the chamber, there is a rotor (rotating part) and a stator (stationary part). Both have specially designed surfaces to create a narrow space between them.

Rotor Rotation Movement:

The rotor rotates at high speed inside the stator, creating a cutting and shearing movement between the surfaces of the two components.

High Pressure and Shear:

The narrow space between the rotor and stator, combined with the high rotational speed, generates high pressures and shear forces. This process causes a reduction in the size of solid particles or liquid droplets.

Shear and Collision Mechanism:

Particles are subjected to a shear, collision and impact mechanism, resulting in the division of particles into smaller sizes.

Opening Adjustment:

Some units allow adjustment of the gap between the rotor and stator to control the size of particles produced.

Product Output:

The final product is discharged from the colloidal mill after reaching the desired consistency.

Features and Advantages:

Fine Grinding and Homogenization: Provides effective fine grinding and homogenization of suspended or emulsion materials.

Continuous Production: It can be used in continuous processes, being efficient for large-scale production.

Particle Size Control: Some models allow precise adjustment of particle size, providing flexibility in the process.

Versatility: Can process a variety of materials, including solids, liquids, and complex mixtures.

The colloidal mill is a valuable tool in industries that require size reduction and homogenization of products, especially in food, pharmaceutical and cosmetics production. |

|

|

|

|

Stainless steel colloidal mill.

Bench equipment for laboratories or small production.

Engine with 1/3 CV

R.P.M: 3,500.... |

|

|

|

Brand: Meteor

Industrial colloid mill.

Brand: Meteor.

Model: Rex 1.... |

|

|

|

Brand: Meteor, Serac

Stainless steel filling system for large containers, buckets, and barrels.

Filling and dosing machine for buckets up to 50 liters.

Composed of:

– 2 Digital Scales 3101C – Alfa Instrumentos (60 kg)

– 4 Stainless steel roller conveyors with... |

|

|

|

Brand: Meteor

Components: WEG

Stainless steel colloidal mill.

Manufacturer | Brand: Meteor.

Model: REX-III/II/K.

Year: 2003.

Operating: 5 years.

Shutdown: 3 years.

WEG electric mill motor. Voltage: 380/660 V. Model: 200 M. Current: 57.3/33.0 A. Power: 40 HP. Spe... |

|

|

|

Brand: Meteor

10 HP stainless steel colloidal mill.

Manufacturer | brand: Meteor.

Model: Rex II

Flow rate: 200 - 2000 liters.

Hopper with a capacity of 20 liters.

With recirculation system.... |

|

|

|

Stainless steel colloidal mill for homogenizing, emulsifying, grinding, among others.

Manufacturer | Brand: Nocelli.

Model: N80.

Approximate capacity: 300 to 1000 kg/h.

Power: 4 HP

Year: 2023.

Operating time: 6 days.

For pastes o... |

|

|

|

Brand: Incal

Line for emulsification processing, homogenization of condiments such as mayonnaise, ketchup and mustard.

Geiger type food processor.

Composed by:

- Processor emulsifier coated in stainless steel with sanitary finish.

Manufacturer: Incal.... |

|

|

|

Brand: Meteor

Colloidal stainless steel mill.

Mill for: Emulsification, homogenization, deagglomeration, mixing, moistening and milling of liquid products to highly viscous.

Maximum capacity: 300 L / H.... |

|

|

|

Colloidal stainless steel mill.

Model: CH2.

Capacity: 500 up to 4,000 liters hour.

Micra of the mills: 2-50 μm.

Power: 11 Kw.

Weight: 250 kg.

Dimensions:

Length: 800 mm

Width: 640 mm

Height: 1,200 mm... |

|

|

|

Colloidal stainless steel mill.

Production: from 500 L up to 3,000 L / h.... |

|

|

|

Brand: Tetra Pak

Components: Allen-Bradley, Danfoss, Rockwell

High shear homogenizing mixer for food.

Manufacturer: Tetra Pak.

Model: B200 - 100VA.

Year: 2010.

Estimated production: 100 L per batch.

With adjustable shear intensity.

Possibility of non-aggressive mixing.

Heating and cooling b... |

|

|

|

Benchtop colloidal mill in stainless steel.

Model: JMS60.

Year: 2018.

Origin: China.

Approximate capacity: 60 kg.

Suitable for making peanut butter and other seeds, such as sesame.

Voltage: 220 V Single Phase.

Power 2.2 KW.

We... |

|

|

|

Brand: Meteor

Moinho coloidal em aço inox.

Marca: Meteor.

Modelo: REX 2 II.

Motor: 10 cv.

Moinho molhado, para produtos húmidos, dispersão, emulsificação, homogeneização, desaglomeração, mistura.

| |

|

|

Brand: Meteor

Components: Coel, Merlin Gerin, Secon, Telemecanique

Horizontal colloidal stainless steel mill.

Brand Name: Meteor.

Model: Rex II.

QFC.

380 Vac.

20 A.

3 KA.

10 Hp.

Components:

Telemecanique.

Coel A2E.

Merlin Gerin Multi 9.

Secon.... |

|

|

|

Brand: Shanghai Zhuheng Industrial

Stainless steel colloidal mill.

Manufacturer | brand: Shanghai Zhuheng Industrial.

Model: JMF-80.

Approximate production capacity: up to 150 kg / hour.

Granulometry (adjustable) from 20 to 40 microns.

With 30-liter feeding tank.

For... |

|

|

|

Brand: Meteor

Colloidal mill.

Brand: Meteor.

Model: H-3 / 15.

Video click here.... |

|

|

|

Brand: Meteor

Colloidal 316 stainless steel mill.

Brand: Meteor.

Model: Rex III.

Capacity 2100 at up to 7000 liters/hour.

Motor: WEG 30 CV., stainless steel cart, etc.

OCCUPATION

Dispersion, emulsification, homogenization, deagglomeration, mixing, ... |

|

|

|

Brand: Fryma, Frymakoruma, ProXES

Food processor.

Brand: FrymaKoruma

316 L stainless steel cabinet.

Engine: 3 hp, with 3450 rpm, closed vacuum system, disperser, product inlets, control panel.

The products to be processed are fed directly into the homogenizer.

They retri... |

|

|

|

Brand: Fryma

Colloid mill.

Brand Fryma.

Stainless steel 316 L.

Power: 5 hp.... |

|

|

|

Brand: Fryma

Colloidal stainless steel mill.

Brand name: Fryma Koruma.

Stainless steel: 316 L.

Engine: 3 cv.

At 3450 rpm.

vacuum closed system, disperser, product inputs, control panel.

The products to be processed directly in the homogenizer.

... |

|

|

|

Brand: Meteor

Colloidal stainless steel mill.

Brand Name: Meteor.

Model: Rex II.

Production: 2000 L / H.

Engine: 10 HP.... |

|

|

|

Brand: Meteor

Colloidal mill for homogenization.

Brand: Meteor.

Model Rx III.

With production up to 7000 L / H.... |

|

|

|

Vertical colloidal grinder type II homogenizer.

Made of 304 stainless steel for liquid and creamy products with capacity.

Capacity: 3000 liters / hour.

with 10 CV / 7.5 KW engine and return spout, ready to produce.

It has the function of ... |

|

|

|

Vertical colloidal mill.

Type: III.

Homogenizer.

Made of 304 stainless steel.

For liquid and creamy products.

Capacity: 500 to 4000 L / H.

10 HP motor.

Power: 7.5 KW.

With return spout.

Ready to produce.

For products: se... |

|

|

|

Vertical colloidal mill.

Type: III.

Homogenizer.

Made of 304 stainless steel.

for liquid and creamy products.

Capacity: 500 to 4000 L / H.

10 HP motor.

Power: 7.5 KW.

With return spout.

Ready to produce.

For products: ... |

|

|

|

Colloidal mill for peanut paste in stainless steel 304.

Model PA-JMF 120.

With 30 L feed tank, it allows continuous milling for pulp production, in single pass through the colloidal turbine.

Technical specifications:

Model: PA - JMF120.

... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|